Home

Learn

Trending Topics

Expansion could be possible with what you already have

Expansion Could Be Possible with What You Already Have

Almost everyone is thinking about how to expand their business, or at least increase profitability one way or another, and for many dairy farmers with both large and small herds, robots are becoming the solution.

Many dairies across North America originally built a milking center connected to a freestall housing facility and have since expanded the size and number of barns and increased the number of cows to the maximum capacity of the milking center. Now that the existing facility is maxed out, robots could be a great solution for continued expansion.

This approach allows you to start with a small number of robots and add on and continue to transition away from the current setup in a way that works for you. Gradually expanding into automatic milking with robots can provide a way for dairies to address growing challenges as well as prepare dairy management to succeed in a new frontier.

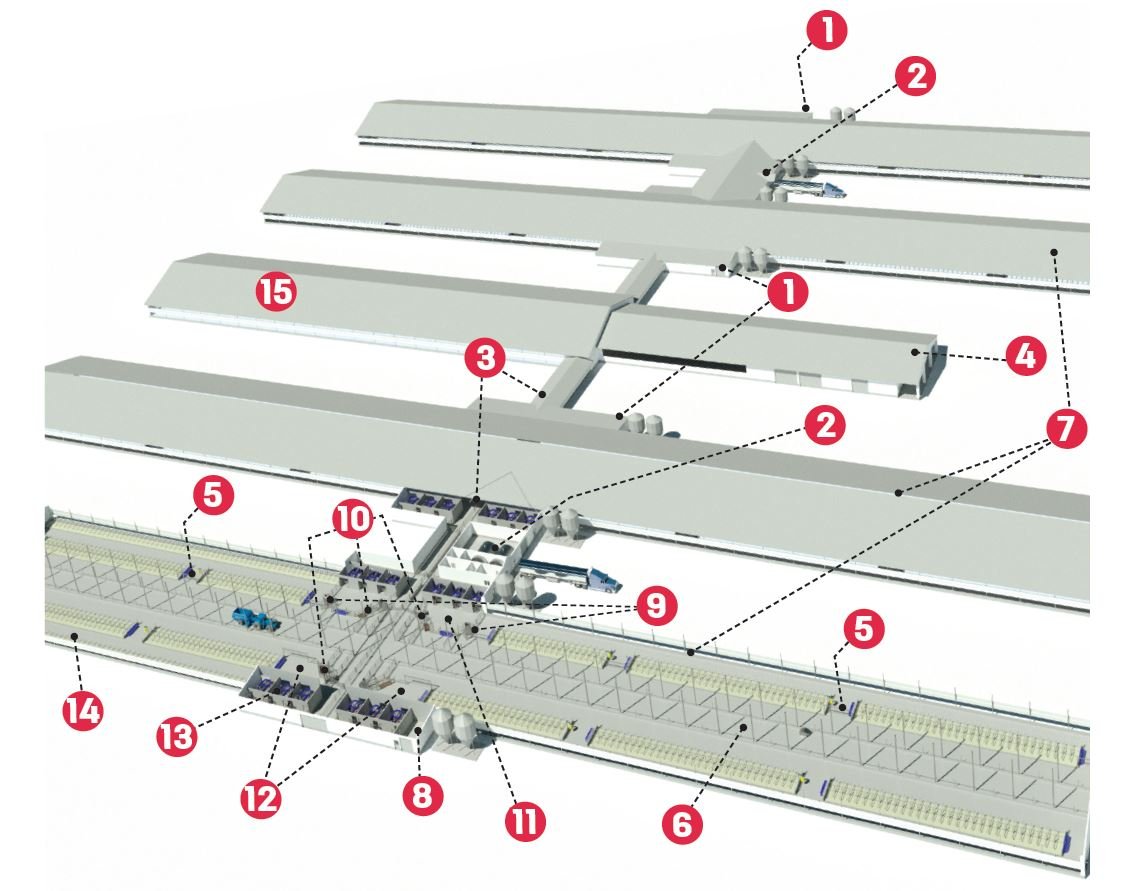

In the example shown here, an existing 3,500-cow (plus or minus) facility has been converted into a robotic facility by adding lean-to structures and new, centralized milkhouse facilities.

Illustration credit: Progressive Dairy

- Lean-to addition with equipment room for robots

- New structure between existing barns with robot rooms, milk house, equipment, office etc.

- Existing transfer lanes to remain in place

- Existing milking center

- One-way gates can be added to convert cow flow from free-traffic to modified-guided cow flow

- Self-locking headgates can be added for handling cow at the feed table

- Typical four-row freestall barn

- Equipment room

- Pre-selection gate (guided traffic)

- Post-sort gate (guided or free traffic)

- Commitment pen in guided traffic

- Temporary fetch pen in free traffic

- Robots installed in lean-to addition with little interruption to daily routines during construction

- Typical six-row freestall barn

- Existing special-needs facility can continue being used

To learn about additional considerations for converting to a robotic facility, like management style, nutrition, cow comfort, and cow flow, check out the unabridged version of this article on Progressive Dairy’s website.