Home

Learn

Trending Topics

Free Flow or Guided? You Decide

Free Flow or Guided? You Decide

The farmer can potentially thrive with relatively low labor inputs. Also when the operation is ready to expand, this design has already taken into account future growth.

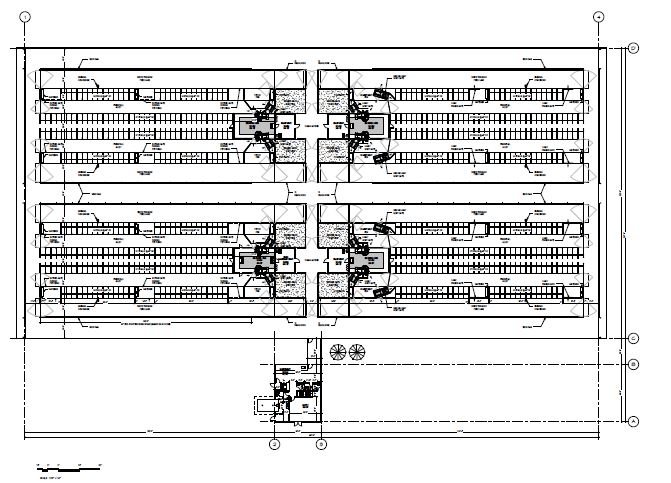

Click on the image below for a larger view:

In summary, this is an eight VMS, free flow traffic, three feed drive, cross ventilated barn with automatic sorting to a bedded Separation Pen. The design is easily adapted to milk first guided traffic and the drawings reflect this; one side is portrayed as free flow and the other as guided flow.

- Highlights:

Flexible and expandable

o Can easily be converted between free and guided cow traffic

o Additional robots can be added in the future by adding more bays to the building - Bunk space

o Approximately 30” of bunk space per cow, allowing all in the group to eat comfortably - VMS Room

o 28” deep pit for easy udder viewing and, in the case of fresh cows, manual attaching of cups

o Clean access to room with no dirty lanes to cross

o Doors to access Commitment Pen

o Tiled floor and PVC sheeted walls for bright appearance and easy cleaning - Post-milk sorting

o Bedded pack Separation Pen behind VMS Room provides utmost comfort for segregated cows

o Headlocks located only in Separation Pen with neck rail in main group, significantly reduced airborne and impact noise when compared to barn with headlocks all around - Pre-milk sorting

o Angled entry for smooth cow flow into the Commitment Pen, particularly when fetching overdue cows - Middle Crossover

o Often overlooked, the additional crossover located in the middle of the outside row gives cows a second option for accessing the feed bunk from the freestalls

o Research has shown that feed is rapidly and completely consumed within 30’ of a crossover, therefore we’ve ensured all 162’ of feed wall is within 30’ of a crossover (note: we consider the Commitment Pen in this design a crossover) - Utility Room adjacent to the VMS Room

o A dedicated place to keep equipment such as water heaters and milk divert units as well as chemicals

o Room located near center of barn for ease of access by people and equipment - Manure handling

o All manure is scraped to a cross trench away from the robots, keeping the milking area as clean as possible with minimum labor input - Walkway between head-to-head stalls

o Allows Herd Manager to walk the barn with better and more complete view of cows - Concrete curbs, not walls, at freestall row ends and crossovers

o Curbs keep manure, sand, straw, etcetera in the appropriate place while not hindering airflow like a 4-5’ wall

The facility we’ve highlighted here is the culmination of years of experience of what works well. Our integrated solutions and more than 130 years of innovative barn designs can help you increase productivity.

Each dairy is unique and has different needs, therefore results are not typical and will vary. Results depend on a variety of factors including good farm and herd management practices.

8 VMS DrawingEven retrofitted barns have the potential to be successful robotic operations. At DeLaval we do all we can when designing a VMS barn to ensure the cows and the operators have the best chance to thrive while keeping the bottom line in mind. In the next addition we will delve into a facility designed for large herds.